No, no. I said name it, not rebut it. What was it?

Rob

For JD’s delectation (or exasperation - if there’s a difference), perhaps Rob should consider re-butting talasiga’s bottom end? Goatishly or surgically. Either will do.

@ROB who may have missed this at page 1

This is Casey speaking on his experience. We cannot deny his experience although we may argue against how he or others may use the fact of the experience in supporting their case.

Not one person in this thread has tried to say that thread can’t be used properly. That’s all Casey has said there, that properly-applied thread doesn’t cause a problem.

Despite what the free-wheeling among us might claim, no one has provided any evidence that it’s impossible to harm a flute with thread. Besides, absence of evidence is not evidence of absence.

Rob

@Rob.

It pays to read the OP, in this case by Terry. It is replete with irrebuttable experience.

It also argues a certain course of action based on the experience.

It admits to not being informed by independent observation and therefore the conclusion that the thread did the damage is not irrebuttable.

WE don’t even know whether the flute was BADLY threaded in the first place.

It is not valid to simply say the thread must have been badly done because of the damage to the wood.

My simple experiment suggestion aims to remedy that (it is on the prev. page) so that Terry may be able to substantiate his position.

Yes, if properly-applied thread doesn’t cause a problem then we need to know whether the threading for the OP flute was badly applied.

QED

I like the part where we lock the thread for 11 months while we await the results of your experiment.

No thanks.

Rob

I haven’t gotten around to that experiment yet - but don’t think I need to at this point. I realized tonight that I have a good “real world” example of a boxwood flute with thread on it, that has been in my workshop since 2003. Its my Rudall template that I turned for myself out of a choice piece of curly boxwood. I’ve kept it thread wrapped all this time, but haven’t rereamed the bore since manufacture. I use the same exact reamer for the bore on my current Rudall models as on this flute, and this week I just happen to be working on and finishing up two other curly boxwood Rudalls. When I get to work in the morning I’ll measure up these bores and compare it with the old one. This flute hasn’t been played much - but has been played enough to be broken in. I use this one on the rare occasion when I attend a session (most of the time I couldn’t play a good reel to save my life - though I have no trouble playing a Galician Muniera etc. on the flute or gaita).

Will see if thread wrappings on a flute for nearly 8 years have caused any bore compression - and whether or not this has made any significant difference.

Stay tuned for the results…

Geesh - 16 pages about this. This cork vs. thread controversy is bigger than the “which flute material makes the best flute” controversy of the 19th century! I remain unconvinced however - am sticking to my user friendly thread wrappings. Even if there is a little bit of bore compression, this is easily corrected if necessary.

Casey

I think you’ve lost your thread, Fred. No one said 11 months.

You called me out. I came out - answered your points with evidence from this topic

logically, thoughtfully, succinctly and this is your response?

With respect Casey this is as deficient as the other approach. The idea is that BADLY done threading is the cause and I doubt that this is the case here.

You’re right, it was 13 months. I’m not sure that’s an improvement.

Still looking for that logic you’re referring to. Ditto the “evidence”. We’re clearly not even talking about the same thing, so don’t expect a different response either.

Rob

I am just simply looking for evidence on this 8 year old flute of this phenomenon. If its there, it will be measurable. Its absence may simply indicate that I wrap my flutes in a way in which this doesn’t happen. It will also indicate if it is something I should be concerned about on my flutes, at least the boxwood ones. Its not a flawed experiment. Results in a few hours… gotta have breakfast and read my email/facebook crap/news and do a few other things first. Will post around noon PST.

Casey

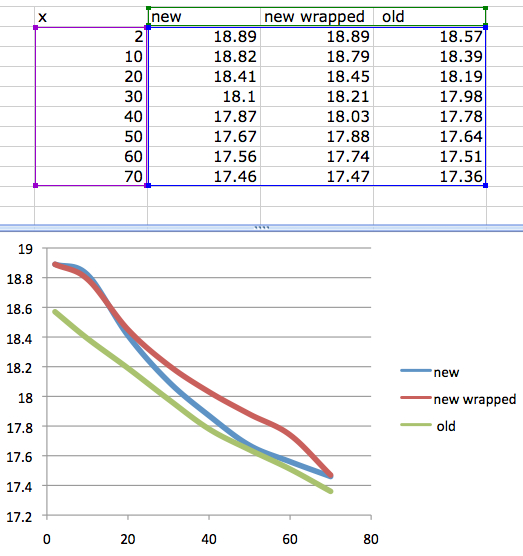

Here are some data:

The flutes measured we all reamed using the same reamer. The tenons are 30mm long. Bores were measured to just before the 1st hole. Three flutes were measured: a new one, unwrapped, reamed on Thursday, a new one, finished in early November, wrapped and assembled, and an older one that was made in early 2003 and has been wrapped and stored assembled for years. It has not been rereamed. Note the radically different bore profiles! Boxwood is a wild animal and moves on its own. I would estimate the range of accuracy of these measurements to be around .10-20mm. I used a telescoping bore gauge which I would insert to a constant depth, then release and set the gauge, then measure with digital calipers which measure to .01mm.

The final bore profile is not determined on my flutes by reaming. After tuning and voicing, there are bits of wood hanging about the tone holes, and so I use sand paper of various grits wrapped around a steel rod rotating at 3200RPM to sand the bores. This might explain some of the bore differences, in addition to how much boxwood moves.

The two new ones show a similar bore across the tenon. It may be when I designed this reamer I took bore compression under the tenon into account to arrive at the bore profile of the old one down the road. I really can’t remember. This may just be an artifact of my last reamer sharpening. The original bore profile of the reamer used was based on a late Rudall and Carte in Cocus owned by Nick Voreas, which didn’t have any compression at the tenon.

Note that the 2003 vintage flute is not “strangled”.

Sharpening a reamer can change a bore profile quite radically. To me the bore is just a starting point. I use bores in my flutes that allow for some plasticity in terms of where I can place tone holes. On my Standard flutes I use the same bore for my smaller handed flutes as my Large Holed Standard. Its the holes, where these are positioned, and how they are undercut combined with the embouchure parameters combined with where the tapered bore starts that guides my flute design and how I make my flutes play. I don’t obsess about bores unless playing with the other parameters stops working as well. Then it is usually time to resharpen the reamers. If I was in the business of making historical copies and claiming accuracy, then I would worry more over the bore pattern. My Rudall is based on a Rudall, but is not an exact copy. I make no claim of exactness. The main point is that even with an inconsistent bore profile, my flutes still work. Even if the bores are slightly narrowed at the throat. These inconsistent bores will be the focus of some poor grad student in a few centuries, who will think that they can track my progress this way (especially since I stopped numbering around 1987)!

So back to the main issue behind this thread: Is cork better than thread wrapping? Calling a thread wrapped flute “strangled” is kind of a loaded statement that would suggest that cork is better, which is an unfair statement to those of us who thread wrap our flutes instead. Maybe, to be fair, we should call the corked wrapped ones “choked”. One direct effect of this discussion is that I have had an uptick of clients contacting me to ask if their flutes are being strangled and if they should go out and have them corked instead. In all cases the flutes are working fine and none of them have anything to worry about. On the other hand I have had clients go out and cork their flutes, despite my warnings not to. Every single client who has gone out and corked their flutes (usually done by a professional woodwind person) has then found that their sockets cracked. Thus I state in my care instructions that corking will void their warranty. I am sticking to thread.

Future hot topic: Which Metal is Better for Flute Keys? Sterling Silver, Nickel, Brass or Pot Metal? Brought to you by the folks at Excruciating Minutiae Productions…

Casey, this is wonderful news! I know that I (as well as many other players with nothing better to do) have been staying up nights pondering just this vastly important and often overlooked question. Please let me know when this one comes out so I can stock up on popcorn (I’ve about run out over the last 16 pages). ![]()

I was also wondering about the influence of color of wood on tone…

Clinton

I foresee an upcoming mini series on PBS.

perhaps a micro series…

nano series?

![]() there ya go!

there ya go!

That’s promising, Casey, although, at this point, it only addresses the question of one of your flutes, wrapped by your method, not played very much over a life of 7 years, and kept in your climate. I’ve raised a really quite different question - a vintage flute, threaded and probably rethreaded a number of times by probably different people using probably a range of materials and approaches, subjected to at least two climate regimes and definitely played a lot over a hundred and fifty years.

So, between us, we’ve perhaps defined the limits of the discussion, but there’s still plenty to wonder about in between! I’m still holding a flute that has been strangled, and I’m still surrounded by flutes (including some in my collection) that suffer considerable bore compression. Indeed, if we take reversed taper (localised minimum) as the dividing line, some of these are also strangled.

Seems to me, what I’m reporting should be a warning to all to go carefully, until we can answer the question what do you need to do to a flute to cause excessive bore compression. But what people choose to do with their flutes is, of course, up to them.

I’m surprised by your statement “Every single client who has gone out and corked their flutes (usually done by a professional woodwind person) has then found that their sockets cracked.” But I have no reason to doubt it, I just wonder about what it tells us. Is it, for example, possible that, as a threader, you make your tenons stronger and your sockets thinner, whereas I, as a corker, perhaps do the opposite? Or does it tell us that professional recorkers are used to clarinets, with their thicker walls, and pack the cork in too densely for the thinner wood of a flute? If so, flute owners need to warn their woodwind recorkers about this danger. Do the recorkers carefully tailor the cork thickness to the gap between tenon trough and socket, or do they assume the maker will have sized the gap appropriately, and all they have to do is put some standard thickness cork in there? This would be a bad mistake as a maker who uses threads would have no reason to size for cork.

And, are we talking flutes with rings here, or all wooden construction? I do think corked tenons need sockets with metal or hard plastic rings to support the open end during fitting. (Or, dare I say it, thread?!) I also go for tapered sockets, so that there is no force on the socket until the cork snugs up towards the end of insertion.

I don’t think the word choked is really apposite in the too-much-cork situation, as it still implies strangulation of the tenon. The problem here is splitting asunder of the socket, so “overpacked” or “stuffed” would seem more the direction we need to describe. A competition to come up with the most colourful descriptor follows …

Anyway, good to have defined the range. Now all we need to do is work out what lies in the middle. The next 17 pages might get us closer! Heh heh…

Terry