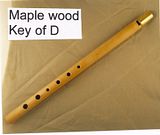

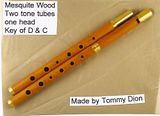

‘‘Whistles of Wood’’ are made in Santa Fe, Texas by Tommy Dion. You may click on the thumb nail pic to see it larger or go to e bay to read more about them. e bay link click here http://shop.ebay.com/tommyiving/m.html

All four whistles have sold on Ebay. Many thanks to the C&F members that bought or showed interest.

I have listed another one part Maple Wood key of D, ( http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&item=280605466859&ssPageName=STRK:MEWAX:IT#ht_720wt_1062 ) and also am making a few more of Maple. Send me a PM or email if your interested in a Maple ''Whistle of Wood".

Hey C&F folks,

I just bought one of Tommy’s maple D’s on eBay because I recently came into possession of a dymonwood whistle Tommy made several years ago and I love it. Can’t wait to get hold of the maple one. Tommy is a great guy. Buy some of his whistles! They are in tune and well balanced with medium loudness so you won’t wake the neighbors. I’m really happy about mine.

Pretty stuff Tommy.

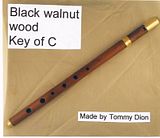

How was working with Walnut? I’ve steered away from it because it’s a pretty porous wood, but it sure is beautiful stuff. Did you do anything in particular to seal the grain?

Thank you for the compliment ecohawk. Your Maple ‘‘Whistle of Wood’’ is in the mail and should be there soon.

Thank you Paul. Working with black walnut was like any other wood in that maintaining sharp tools is most important. I have used walnut from two different sources and one was tighter grained. I sealed the black walnut C with sweet almond oil and it plays fine. I made a D whistle with the porous grained walnut and sealed the out side with very thin cyanoacrylate glue. It penetrated all the pours but left it with a dull finish. I then coated it with thicker glue and was able to sand it to a high gloss. Word of caution here now. When working with that much super glue don’t assume the whole thing is dry after touching it. The bottom side could still be wet and grab your fingers. Always have some remover around. Now I rub super glued surfaces with a rag to test if it is dry. Removing a glued rag is more easy than fingers. lol

Here is a little sound clip of it. Just click on the picture.

I’ve used this stuff on very porous woods:

http://www.minwax.com/products/maintenance_and_repair/high_performance_wood_hardener.html

I make a small trough of aluminum foil just big enough to hold the top and bottom of a whistle. Once the wood is bored, rough turned and rested for a month or so, I put it in the trough and pour in the wood hardener. I let it sit there for 20 minutes or so, turning it once in a while. Then I take the pieces out and let them dry vertically. I give it a couple of days to really cure in a warm place before resuming work on the wood-- I usually need to re-ream the bore. The results have been quite excellent.

Does the bore still need to be sealed with an oil or is it left like dymondwood.

I think it’s pretty waterproof at that point, but I apply some oil just for the heck of it.

As a recovering recorder player who occasionally backslides, I was intrigued by my new Tommy Dion maple whistle which arrived yesterday since it is my first “wooden” whistle. I own another Tommy whistle made of Dymonwood which I’m told doesn’t need oiling. Right out of the box literally, I noticed that same beautiful tone which clearly marks Tommy’s whistles. A breath of chiff with clear and nicely balanced octaves.

However, the recorder geek in me immediately screamed, “oil this thing before you take it home to that forced air house of yours in San Francisco because if it cracks you are going to be really upset!” So upon my arrival at home I took out the trusty almond oil and warmed it a bit before swabbing inside and out. I let it sit for an hour which is my normal procedure, then wiped off the excess and let it sit overnight.

I stuck it in my pocket so I could play it on my train ride to work. Well, this whistle is amazing and that’s all I can say. Tommy, I’ll be ordering another one in a different wood right after the holiday.

Thanks brother.

Michael

Thank you for the compliment Michael. Almond oil is what I use. Also have tried olive oil and could find no difference. After wiping excess oil off the outside you can polish it or leave it alone. The wood has been burnished to a high shine. To maintain the shine put the whistle flat on a towel over a table. Get a piece of clean brown paper bag and rub the whistle long ways with the grain and move it back and forth on the towel. You do not need to rub hard.

Do not hold the whistle in the paper and twist it. This will leave rotation marks.