Whew, this thread is moving fast - excuse me if I can’t keep up!

Like Rob, I thought to ask someone whose grasp of physics is just a little better than mine. Professor Neville Fletcher, Research school of Physics and Engineering at the Australian National University in Canberra. Neville’s also a flute player. You can meet him at Contact us. I’ll relay his response in full with comments from me in [square brackets].

Hi Terry

Fortunately those questions are fairly easy to answer. [Whew, I had feared the worst, calculus!]

If you tie a string around a tube of radius R with string tension T, then the inwards radial force on the tube is T/R per unit length of string. So if the tension is 700g (I presume you mean grammes weight) [yep, sloppy me!] and the tube radius is 1 cm, this gives 700g per cm length of string. [And since there are 2pi radius-lengths of string around the tube, that will mean our 700gm tension actually applies a force of 4.4KG inwards. Gasp, it’s worse than we thought!]

This can’t be readily converted to a pressure, since the string is very narrow – it would be easier with a ribbon.

[Fair point about calculating the pressure, as a single string, being theoretically round, will only make a theoretical single infinitely-thin line-of-contact with the tenon, and therefore any force at all on the string will produce an infinite pressure. We know of course that the string will flatten out, but the amount it will flatten out and spread the force around is hard to determine. Back to Neville…]

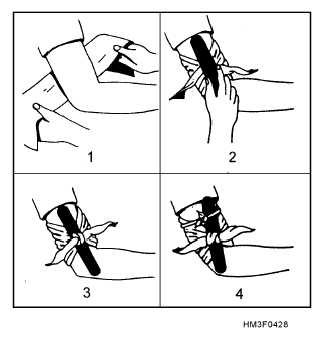

If you put 150 turns side-by-side with the same tension then you get 150 times the inwards force, but it is presumably spread over 150 times the area. [I.E. the force goes up, but the pressure remains the same.] Similarly 13 layers on top of one another adds to nearly 13 times the force, except that you now need to use a slightly larger average radius in the calculation. [And this time the pressure will also go up 13 times, as the area hasn’t been increased.]

[I don’t think we need to calculate the force, other than to recognise that, unless we wrap very lightly indeed, it is going to be very high. This next bit is interesting …]

Where distortion of the tube is considered, you are both distorting the local radius and also the longitudinal shape. [Someone asked sometime back, had the tenon shortened? The answer is probably - it’s about a mm short of the socket depth. But of course, we have no way of knowing how close they were originally.] The force per unit area [pressure] is probably what matters in the first case [compressing the diameter], and the total force in the second [shortening the tenon], since you are bending the wall of the tube as well as compressing it.

I hope this helps.

All the best for the New Year.

Neville

Certainly helps, but makes it even scarier!

Terry