Contacted a few days back by an owner of one of my flutes who had found his tuning slide had seized up. I told him of my theory that this is caused when we allow too much breath condensate to build up in the space between the inner and outer slides. It then finally congeals into a glue strong enough to defy our ability to twist it free.

And passed on my usual advice that introducing a hot metal rod up through the barrel socket to the overlap area, and rolling that rod around the inside of the slide will warm it enough to weaken the breath condensate glue, and let the slide come apart, usually at that point in time where you are about to give up in frustration!

Some time later, I remembered that not everyone was really convinced about the breath condensate theory, and wondered if there was a way I could test it. Without my thinking cap firmly in place, my default condition, I pulled apart the slide on my own playing flute, and wiped off the two mating surfaces with a tissue dampened with methylated spirits (de-natured alcohol). So I now had two clean surfaces.

I sat down in my thinking chair - a nice comfy recliner - and breathed on both tuning slide surfaces in turn. Onto the exposed section of the head slide, and into the empty slide protruding from the barrel. Rotating each victim to get good even coverage of anything that was in my breath. Not huffing or panting, just breathing. I believe I could see the surfaces become a little foggy, but hey, wishful thinking?

After a few minutes breathing, I slipped the slides back together again and rotated the head numerous times to spread any moisture around. I then left it overnight.

Today, I found the head not wanting to rotate. I was tempted to put some muscle into it, but then fortunately my pre-historic scientific training kicked in and a little voice said “measure it”. Err how, I asked the little voice, but it had shot through, no doubt to bother some other non thinkers. It must lead a very busy life!

What am I supposed to measure, I asked from the safety of my thinking chair. The rotational force required to break the condensate seal, the chair offered helpfully. “Torque”, it prompted. I was whisked back in time to high school physics, where our teacher opened the discussion on rotational force with the old gag “Wherever there is a couple, there will be torque.”

Hmmm, so what can I couple to my essentially cylindrical head to be able to introduce and measure some rotational force?

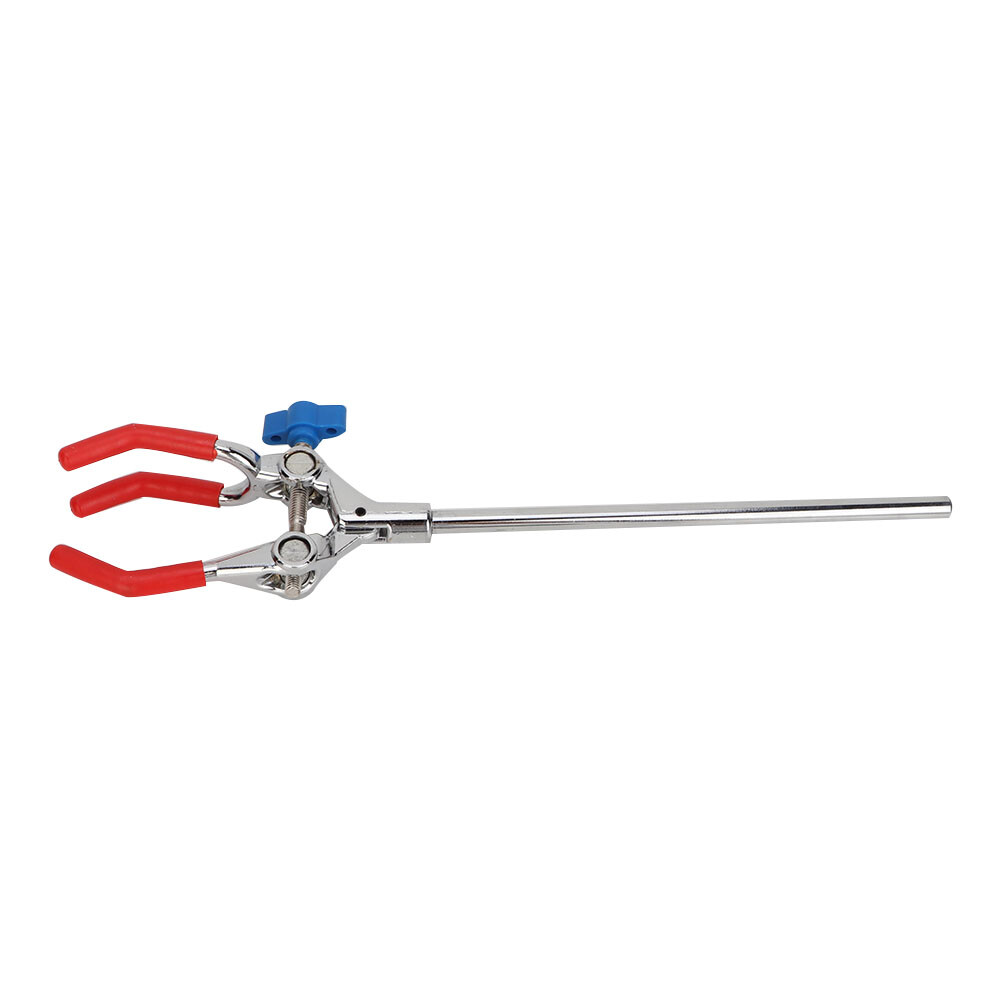

I settled on a retort stand flask clamp, this kind of thing:

So, I clamped the jaw of this thing to the head of my flute, held the barrel and started adding lab weights to the far end of the shaft which I had sticking out horizontally. At 400 gms, the head suddenly rotated. The clamp itself weighed almost 200gms, and more than half of that was sticking out, so we can guess it contributed say another 100gms. Making a torque of 500gms weight at about 200mm distance out.

At this point I suddenly thought, wouldn’t it have been good to measure the normal torque needed to rotate the head before the heavy breathing routine. Too late for that, but then I cleaned the slides surfaces once again with alcohol, greased them lightly with cork grease, rotated them and slid them in and out to distribute the lubricant, and then put the clamp back on intending the measure the torque now needed.

The off-centre weight of the clamp alone (we estimated at maybe 100gms) was now enough to cause the slide to rotate.

So, I think we’ve shown that breath condensate can be artificially introduced, and is capable of gluing a well cleaned slide closed after only a few minutes of application. And that we can easily come up with ways to measure the difference.

Hopefully, I’ve now convinced you all to go and clean your flute slides!