I seem to be coming across a lot of 19th century flutes recently that, frankly, one can only shake one’s head at and wonder “were these guys serious?”.

The flutes look good on the outside. They had to look good, or nobody would have bought them. It’s only when you lift the bonnet and take a close look at the engine you spot the problems.

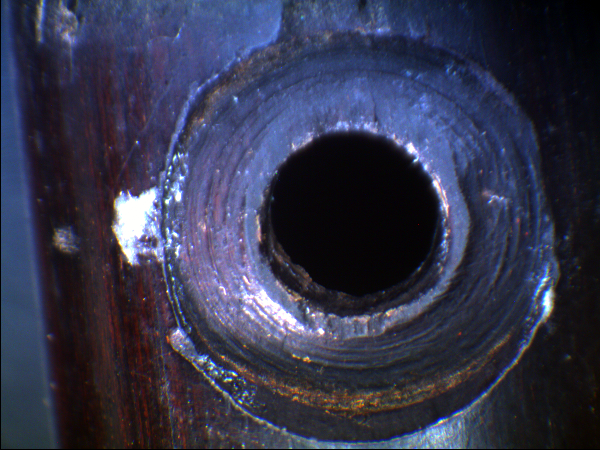

I’m currently working on a 19th century piccolo, stamped only “Improved London”. It came without a head, and with a totally mangled barrel, so I’ve had to make those parts new. But it’s when I then came to clean up the keys and repad them, I came across the evidence I’m about to show you. Imagine you are flying in an aeroplane above a dormant volcano. You look down. You expect to see a cone with a hole in the top. Not a war-ravaged battlefield…

Now, I’m not just being fussy about appearance. No pad is going to seal well against a surface like that. I tried, and it didn’t. Interestingly, the pad really tried. I left it on overnight, and its seating had definitely improved. When I took it off, it looked like the mirror-image of what we see above. But there’s a limit to how far we can expect even fine leather to mould itself. And air is very thin and can sneak through any remaining gaps. And did. The Magnehelic flute leakage detector dismissed it as a joke.

The strange thing is that it doesn’t take long to fix, and it fixed beautifully. I didn’t have a tone-hole cutter small enough for a piccolo, so I had to make one up. Took about 25 minutes to make, and, I’ll admit, it looks like it. Rough as guts. But it cut perfectly and left the surface of the seat gleaming. (Cocus wood cuts superbly if asked nicely.) More than that, the pad sealed as soon as I heated the back of the keycup to let it take up its new position.

So, why had they perservered with a clearly blunt cutter that ripped out the grain rather than sliced and polished it? I just shaped my new cutter on the offhand grinder, cleaned it up on a whetstone, and then touched it up with an arkansas hand stone. All by hand - no tool & cutter grinder. To take the cutter they used and resharpen and hone it would have taken 5 minutes tops.

I had to redo all 6 keyseats on this piccolo. It’s now playing well, and the tuning is surprisingly good. So there was nothing wrong with the design. It begs the question - did it ever play really well at any time in its entire life? It’s hard to imagine that anything other than shoddy workmanship left the seats looking like that. The realities of “made for the trade”, I guess.